|

鍝佺墝: 鍒╄吘杈近/span>

浜у湴: 骞夸笢涓滆帪 绱㈠彇璧勬枡鍙婃姤浠饵/span>

浜у搧浠嬬粛

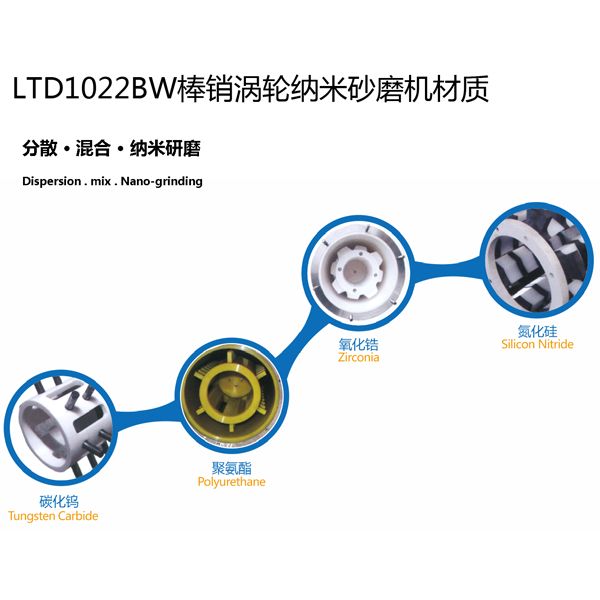

1銆佸甫閿€閽夌殑娑¤疆缁撴瀯杞瓙锛屽叿鏈夊己鍓垏鍔涖€佸姩鍔涘垎甯冨潎鍖€銆佺爺纾ㄨ厰鍐呯墿鏂欏拰浠嬭川娴佸姩鎬уソ绛夌壒鐐癸紝鑳藉疄鐜板鐗╂枡鐨勯珮鏁堢爺纾ㄥ垎鏁o紝鐮旂(缁嗗害1渭m鈥?0nm锛 2銆侀噰鐢ㄧ蹇冨紡鍒嗙鍣紝鍏锋湁杩囨祦闈㈢Н澶с€佸垎绂绘晥鏋滃ソ銆侀€傜敤瀵垮懡闀跨瓑浼樼偣锛 3銆佷娇鐢ㄨ€愮(鎹熴€佽€愯厫铓€鐨勯泦瑁呭紡鍙岀闈㈡満姊板瘑灏侊紝骞堕厤缃簡鏈哄皝娑︽粦鍐峰嵈鐩戞祴鍜屽帇鍔涘钩琛℃満鏋勶紝鏈哄皝瑁呮媶鏇村鏄擄紝缁翠慨鏇存柟渚匡紱 4銆佸彉棰戣皟閫燂紝鍙牴鎹墿鏂欑殑闇€姹傞€夋嫨鐩稿簲鐮旂(杞€燂紝杈惧埌鐞嗘兂鐮旂(鏁堟灉锛 5銆佺爺纾ㄨ厰浣撴潗璐ㄥ彲浠ラ€夋嫨纰冲寲閽ㄣ€佽仛姘ㄩ叝銆佹哀鍖栭攩銆佹哀鍖栫銆佺⒊鍖栫绛夛紝閫傚悎涓嶅悓瀹㈡埛闇€姹傘€ 鈼員urbinerotorwithpinsstructure,withstrongshearforce,powerdistribution,goodliquidityofmediaandmaterialsingrindingchamberandothercharacters,toachieveefficientmaterialdispersion,grindingfineness1渭m锝?0nm; 鈼咥dopt centrifugal separator, with the advantages of large flow area, good separation and long using time etc ; 鈼哢se the wear and corrosion resistant cartridge double mechanical seal, and configure the mechanism of mechanical seal lubrication and cooling monitoring and pressure balance, easy assembly and disassembly, easy maintenance; 鈼咶requency control, users can select the best grinding speed according to the needs of the material, to achieve the best grinding results; 鈼員he grinding chamber material can select tungsten carbide, polyurethane, Zirconia, silica, silicon carbide, etc., to meet the different customers鈥檔eeds . 浣跨敤琛屼笟 绾崇背棰滄枡銆侀櫠鐡峰ⅷ姘淬€佺鎬ф潗鏂欍€佹哀鍖栭摑鏉愭枡銆佺數瀛愭祮鏂欍€佺閰搁攩鏉愭枡銆佺儹杞嵃鍠峰ⅷ銆佺7閰搁搧閿傘€佸尰鑽€佸寲濡嗗搧銆侀潪閲戝睘鐭跨矇浣撱€佸叾瀹冩柊鍨嬬撼绫虫潗鏂欍€ nano pigment, ceramics ink, magnetic materials, aluminum materials, electronic pulp, zirconium silicate materials,thermal transfer inkjet inks, lithium iron phosphate, pharmaceuticals, cosmetics, non-metallic mineral powder and other new nano materials.

鎶€鏈弬鏁?nbsp;technical parameter

|

鐩稿叧浜у搧

|

|

|